Not all spraying methods are the same.

Drones, aircraft, and ground rigs each come with their own strengths and tradeoffs. This page gives a clear look at how they compare so you can decide what makes the most sense for your farm or spraying needs.

Water Use

Lower With Drones

Drones apply liquid at ultra-low volumes, using only what’s needed to hit the target. This reduces water use by up to 95% compared to traditional ground rigs, and even more in some cases versus aircraft.

Drift Risk

Lowest With Drones

Drones fly low and slow, spraying with downward-facing pressure nozzles that keep product on target. This creates minimal drift compared to crop dusters, which operate at high speed and altitude, and even less than boom sprayers on windy days.

Terrain Flexibility

Drones Can Go Where Others Can't

Unlike ground rigs that require clear, drivable paths and crop dusters that need open, obstacle-free zones, drones can fly in and out of tight, rugged, or sloped terrain. They’re ideal for hilly fields, test plots, wet ground, and areas where other sprayers simply can’t reach.

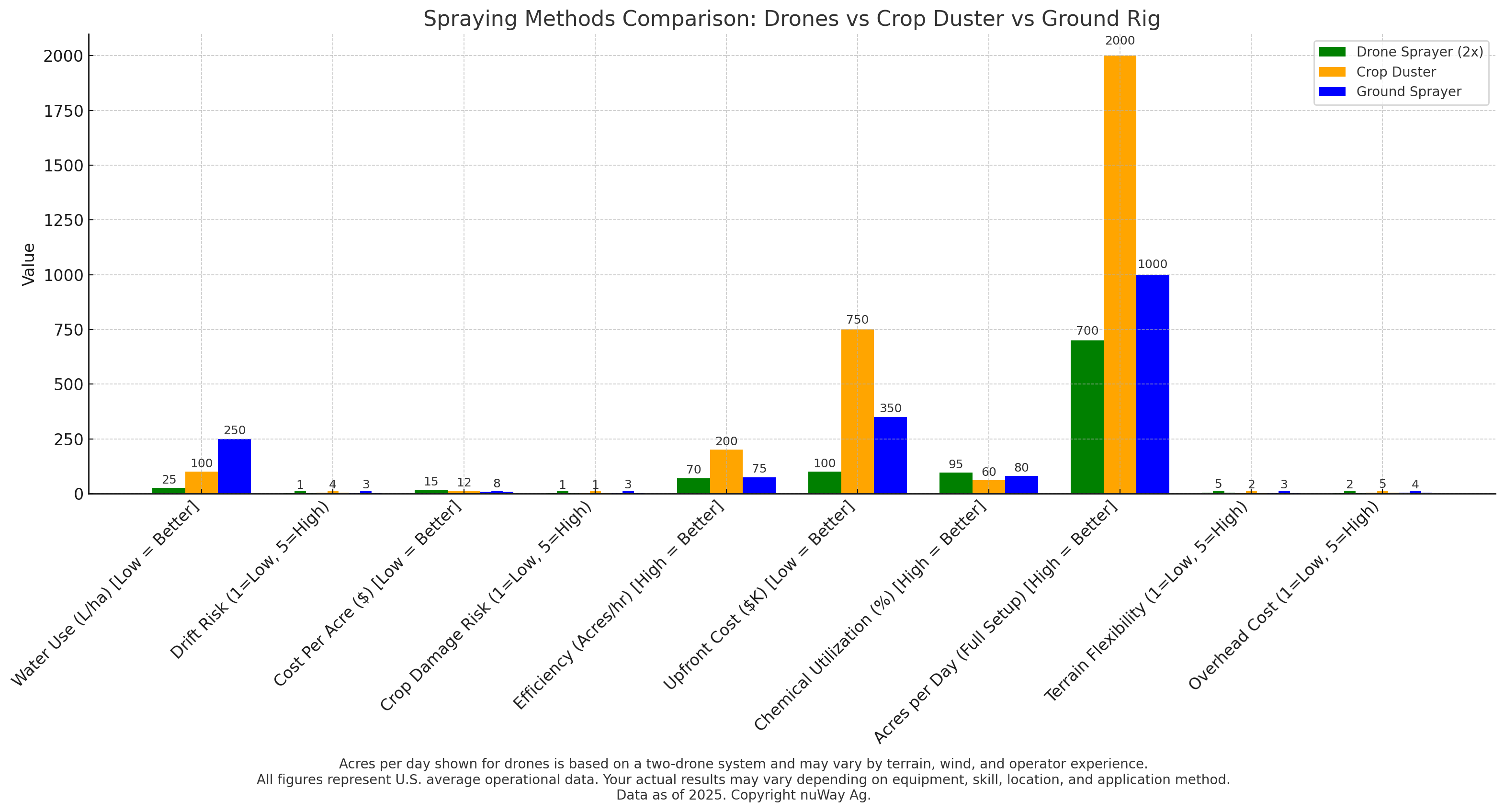

Head-to-head Comparison

How do drones, crop dusters, and ground sprayers really compare where it counts? This chart and table break it down across every major performance factor, including cost per acre, terrain access, chemical efficiency, setup time, and more.

Drone sprayers lead in water conservation, chemical efficiency, and terrain flexibility, especially in rough, wet, or delicate fields where other systems fail. Crop dusters cover the most acres in a day but come with high startup and operating costs, as well as serious drift concerns. Ground rigs can be affordable but are limited by weather, risk damaging crops, and use significantly more water.

These are real-world U.S. averages based on 2025 data. The results speak for themselves. Drones offer a cleaner, more precise, and scalable way to spray in modern agriculture

| Category | Drone Sprayer | Crop Duster | Ground Rig |

|---|---|---|---|

| Setup Time | 5–10 minutes | 30–60 minutes, incl. fueling & prep | 15–30 minutes |

| Terrain Access | Flies over rough or wet ground, and tight spaces | Needs open airspace | Cannot spray on wet ground, or tight spaces |

| Drift Control Quality | Very High | Low | Moderate |

| Labor Requirements | 1–2 operators | Pilot + crew | 1–2 operators |

| Crop Impact | No contact with crops | No contact | Possible crop damage |

| Cost per Acre | $12–18 (avg: $15) | $10–15 (avg: $12) | $6–10 (avg: $8) |

| Chemical Utilization | ≈ 95% | ≈ 60% | ≈ 80% |

| Overhead Cost to Operate | Moderate – batteries, maintenance, chemical gear | High – fuel, maintenance, hangar/storage | Moderate – fuel, parts, equipment wear |

| Startup Equipment Cost | $30–50K per drone; ~$100K for 2‑drone system + trailer | $150K–$750K (aircraft, GPS, hangar) | $150K–$350K (sprayer, tractor, tools) |

| License / Regulation Intensity | FAA Part 107, COA/Part 137, state pesticide license | Pilot license, FAA ag certificate | Pesticide license, standard vehicle operation |

How Drones, Planes, and Ground Rigs Compare in the Real World

Farming has never been a matter of simply doing the job. With decades and years coming and going, the tools evolved from hand-hewn equipment to machines that cover hundreds of acres in a day. As crop needs grow more and more, and prices keep going up, however, farmers are turning to more specialized equipment to get every dollar and every drop worth it.

Spraying is one of the most critical yield protection operations. Whether you're using herbicide, pesticide, or fertilizer, the way you do it can effect your bottom line, your crop's health, and your field accessibility. Drones are the new kid on the block, while aircraft and ground equipment are older reliables from decades gone by. Each has its weak points and positives. The following comparison will help you have a better sense of where they shine, where they falter, and how to choose the best for you and your farm.

What Are Spray Drones?

Spray drones are air-borne unmanned vehicles that employ onboard tanks, nozzles, and GPS to dispense liquid accurately. They're operated by tablet or controller and have the capability to fly programmed flights through your fields even at night.

Because they operate low to the ground and follow exact digital maps, drones apply chemicals only where needed, minimizing waste and avoiding overlap. They’re especially useful in fields with wet spots, terraces, or irregular shapes where traditional sprayers struggle. You can launch them from almost anywhere on your farm, and most models only need a few minutes to refill and get back in the air.

What Is Aircraft Spraying?

Aircraft spraying, often called crop dusting, uses manned planes or helicopters to apply chemicals from above. These aircraft fly fast and low, covering large fields in minutes. Planes can carry hundreds of gallons and operate for hours at a time.

While aircraft are excellent for large, flat acreage with good weather conditions, they require licensed pilots, open airspace, and proper staging areas. The spray pattern can be affected by wind, and it’s harder to prevent drift compared to other methods. Still, for big farms with tight application windows, aircraft remain a powerful tool.

What About Ground Rigs?

Ground sprayers are commonly used for large fields that are easy to access by tractor. They can carry large tanks and apply product at a steady rate. These rigs are usually guided by GPS and can be very accurate, as long as the terrain is dry and the operator can drive through without damaging crops.

In wet or delicate conditions, ground rigs may cause rutting or crop loss. They’re not ideal for post-emergent applications in tall or sensitive crops, and fields with steep slopes or obstacles can be tough to navigate.

How the Three Methods Compare

Precision Targeting

Drones lead in precision. They use digital maps and sensors to treat only the exact zones that need coverage. This reduces chemical usage and prevents spraying near water, borders, or sensitive areas.

Planes can be fitted with tech to help guide the spray, but their high speeds make it harder to control dispersal patterns. Ground rigs offer decent accuracy but only in areas where they can safely drive without damaging the crop.

Coverage Area

Aircraft are built for speed. With large tanks and fast flight paths, they can treat hundreds of acres per hour. Drones treat less land per hour, but they make up for it with efficiency, especially when fields are small, broken up, or oddly shaped.

Ground rigs fall in the middle but are limited by terrain and crop height. They’re excellent on flat, open land in good conditions.

Water and Chemical Use

Spray drones use much less water. Most apply 2 to 5 gallons per acre using ultra-low volume nozzles. This allows you to cover more acres with fewer refills and keeps soil from getting soggy or compacted.

Aircraft and ground rigs usually apply 10 to 15 gallons per acre or more. This increases chemical cost, adds weight, and can lead to runoff if not carefully managed.

Tank Size and Flight Time

Drones carry smaller tanks, usually between 2 and 10 gallons. They fly for 15 to 30 minutes at a time and need regular recharging. Even so, fast refill times and multiple batteries help keep downtime short.

Planes can stay in the air longer and spray more per flight, but each load requires refueling, pilot prep, and sometimes a full airstrip. Ground rigs can carry much larger volumes but are limited by crop stage and terrain.

Crop Damage Risk

Only drones and crop dusters can spray without ever touching the crop. That means no broken stalks, compacted rows, or replant costs.

Ground rigs can cause up to 5 percent crop damage in post-emergent spraying. Aircraft avoid direct contact but may still create uneven coverage due to wind and height.

Operator Safety and Exposure

Because drones are operated remotely, they keep the applicator away from chemicals. This improves safety and helps meet environmental standards.

Aircraft keep pilots high above the field but still risk drift and exposure for surrounding areas. Ground rigs place the operator in close contact with chemicals and can stir up dust and residue.

Total Cost and Efficiency

Drones are the most affordable entry point. A single operator can manage a drone, recharge it with a portable battery, and complete treatments without needing a full crew. They also reduce chemical waste, which lowers input costs over time.

Aircraft require large investments in fuel, pilots, and equipment maintenance. They’re efficient on massive fields but expensive to run. Ground rigs are cost-effective when fields are dry and open, but require skilled operators and still carry the risk of damaging the crop if timed poorly.

Terrain and Flexibility

Drones win here. They don’t need roads, dry fields, or flat ground. They can launch from a trailer, a driveway, or a field edge. Hills, terraces, and mud don’t slow them down.

Planes need open airspace, wide fields, and clear weather. Ground rigs need a way in and out, and good conditions to avoid getting stuck.

Final Word

Every method has a place. Aircraft dominate wide-open acres with time-sensitive needs. Ground rigs do great work where access is easy and timing is right. But drones bring something new, a portable, accurate, and cost-effective tool that gives farmers control over every pass.

As farms get more specialized and inputs become more expensive, the question isn’t whether drones are useful. It’s how can you can start using them.